Therefore, you should phase out wooden pallets in production areas

Many manufacturing companies pack goods on wooden pallets inside the production area itself.

This is not always the best solution, as wooden pallets can sometimes be unclean.

Therefore, it is an advantage to wait to use wooden pallets for the goods to come from the area.

where you produce your products. It may sound awkward, but it is not,

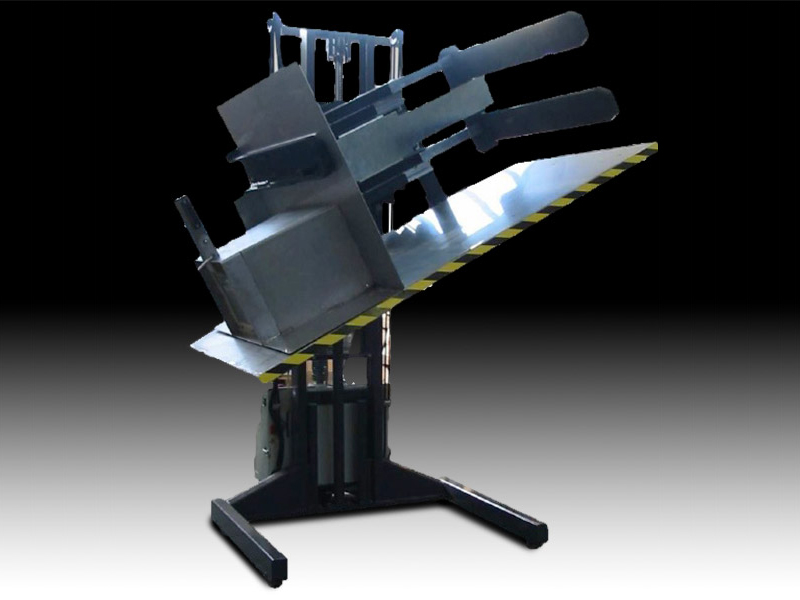

If you have the right machines available. Pallet changers and pallet inverters are good for the purpose,

And here you get more info about the benefits as well as how you can start phasing out the wooden pallets in practice.

Avoid wooden pallets in production

Well, wooden pallets are effective for many purposes, and many companies rely on them.

when the products are to be forwarded.

However, it is not always smart to load goods and objects onto the wooden pallets in the production area itself.

This is partly due to the fact that wooden pallets are often impure. It's not unusual,

that there are bacteria that come with the wooden pallets, and wood splinters are another problem.

When you have a production area, it is of course important that it is kept clean.

Therefore, there are better solutions, and it can for example be to pack the products on clean plastic pallets,

as it is a more hygienic solution.

Change to wooden pallets later

However, wooden pallets can easily be used later. It is easy to move goods around with wooden pallets,

and they can stick to a lot.

Therefore, you can choose to use clean plastic pallets inside the production area,

and subsequently switch to wooden pallets. This switch can be made

when the products come out of the area where they are produced.

An easy place to switch from plastic pallets (or other types of pallets) to wooden pallets is in the warehouse.

Bearings are normally only used for storage, so here there are not the same high demands on purity as there are in the production area.

As long as the goods are packed well enough, nothing happens by using wooden pallets here.

Usually, there is also a lot of space in a store, so having a machine (or more) standing is no problem.

If you have the right machines available, changing pallets is easy and simple. Of course it should never be manual work,

as it leads to wear and tear on the employees, plus it slows down.

Instead, we simply recommend that you get hold of a pallet changer and possibly also a pallet inverter, and that the staff is instructed to use them.

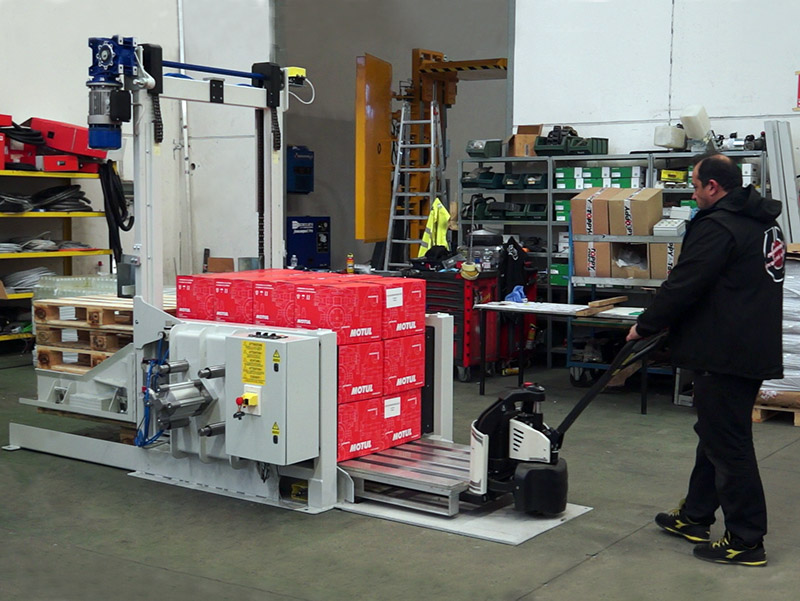

With a pallet changer it is easy and quick to change pallets and it is with minimal effort.

Most companies that choose to phase out wooden pallets from the production area immediately begin to experience good benefits.

It creates better hygiene, and the hassle is less than you might think.

Therefore it is an excellent investment to get hold of the right machines - which, incidentally, also brings other benefits,

For example, if you need to reverse pallets in other respects.

And that saves the employees a lot of trouble!

Check out the best pallet changers and pallet inverters

If you are ready to take a closer look at pallet changers and pallet inverters, check out our selection.

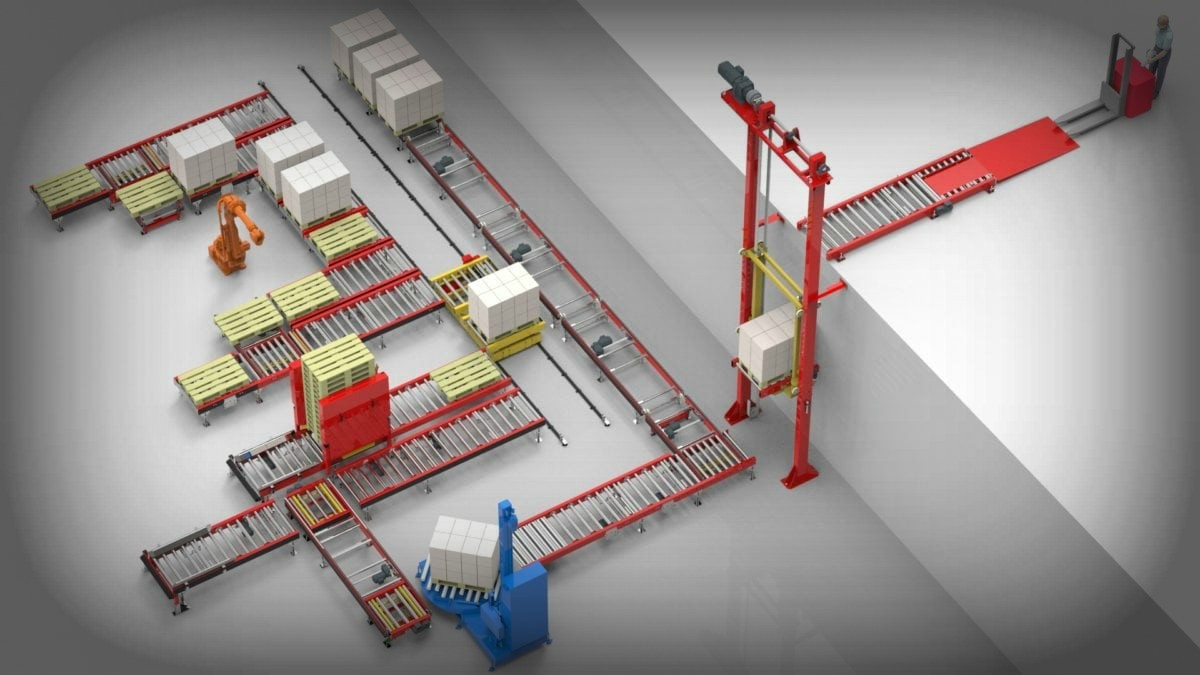

We have both machines for stand-alone solutions, which means that they can be installed independently of other systems that you may have in the warehouse.

You can also get a pallet changer that acts as an in-line solution if you have special needs and if the machine is to be part of a larger logistic line.

Take a look at the selection and find some of the machines that are well suited to your business needs.